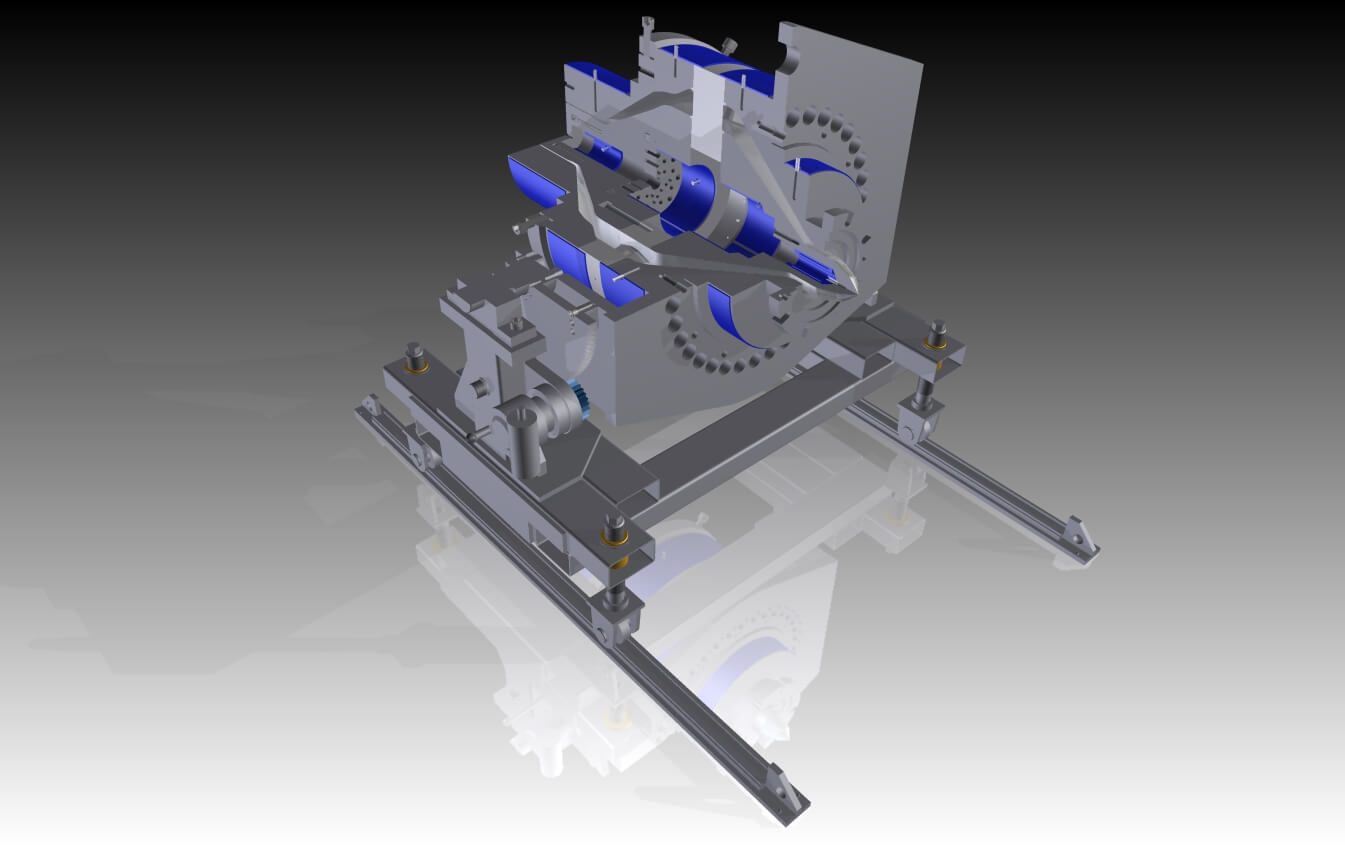

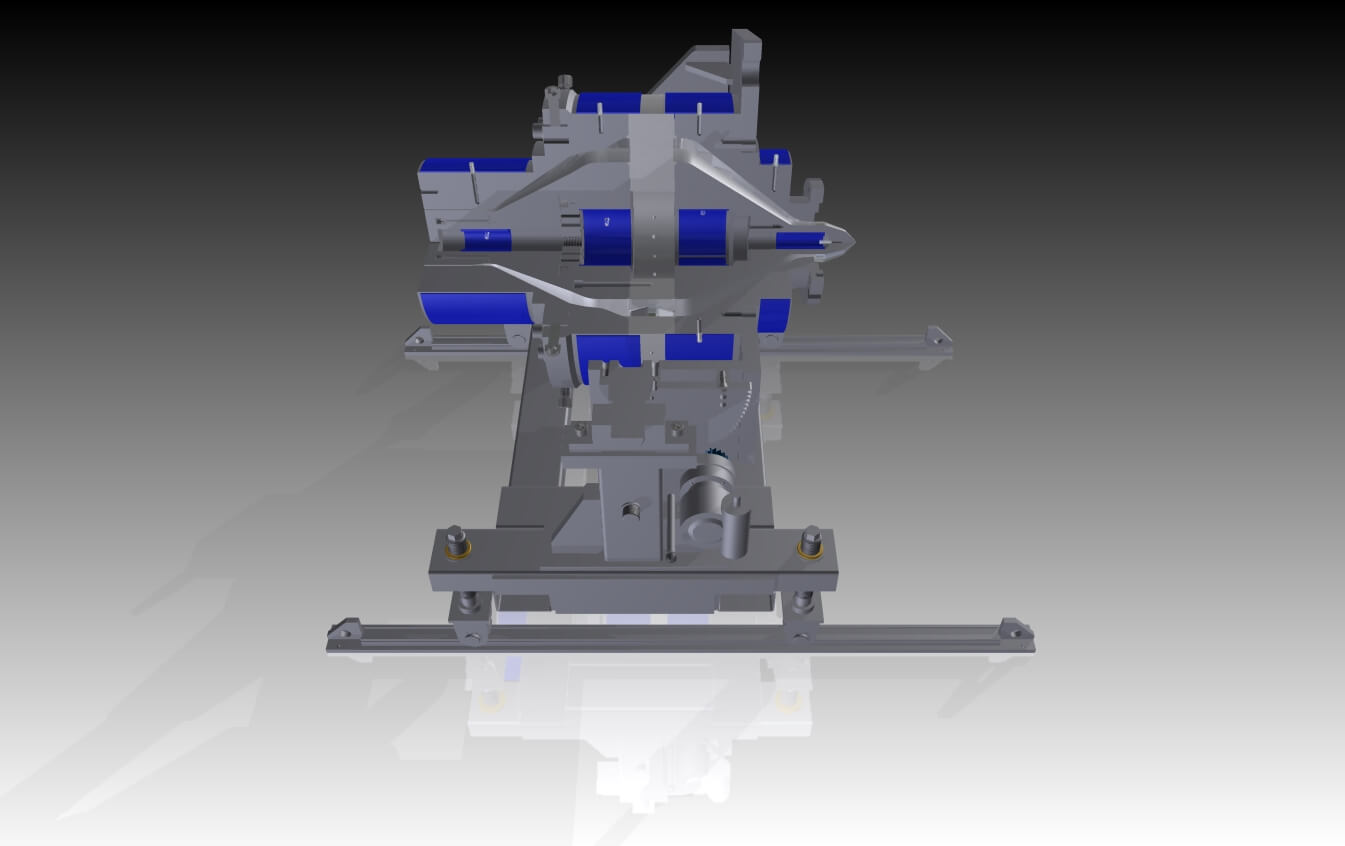

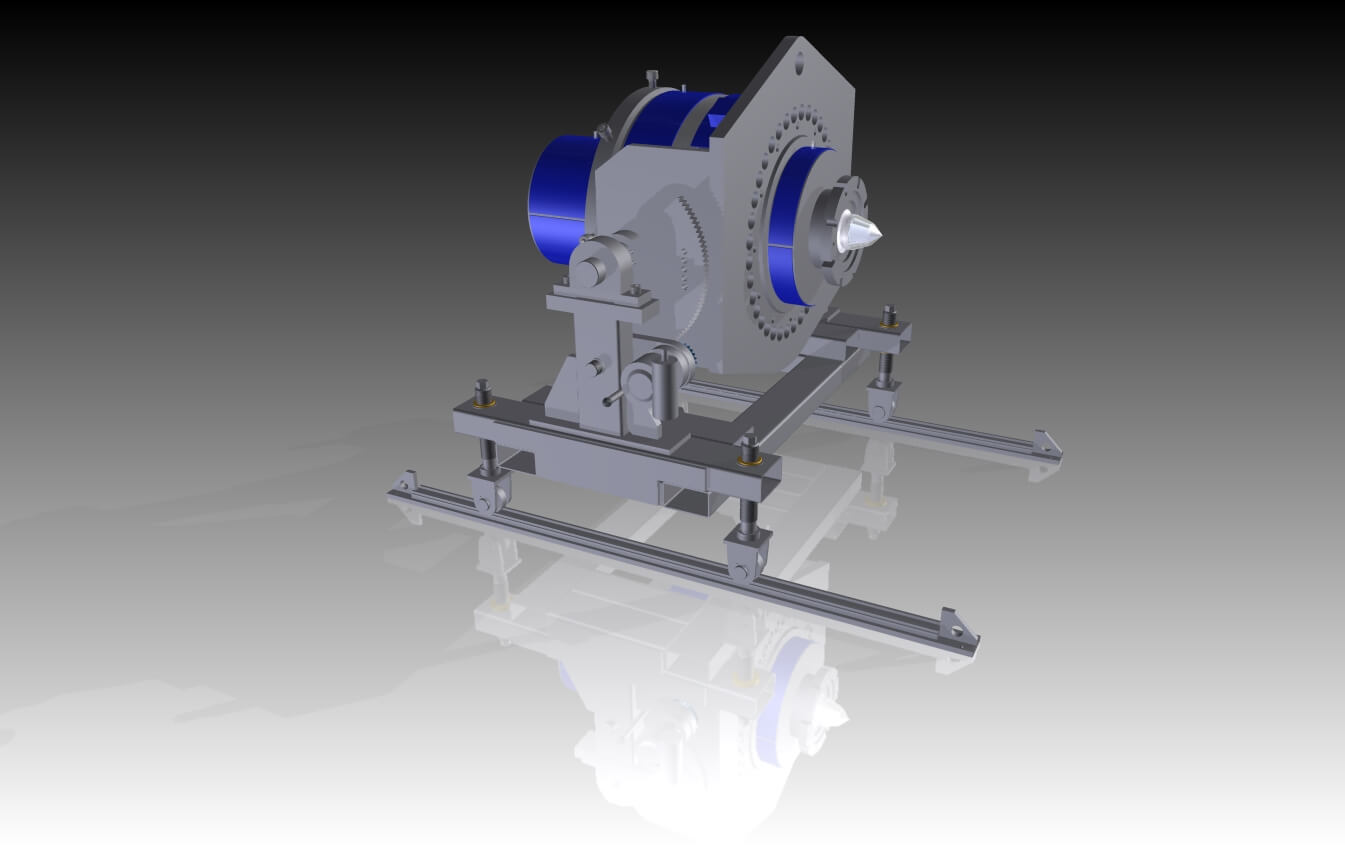

SHORT DESCRIPTION

Models PVC 25 G and PVC 32 G manufactured completely from corrosion resistant tooling steel.

Model PVC 63 G – PVC 315 G is the mandrel assembly manufactured from corrosion resistant steel and melt flow surfaces hardened chrome.

Model 400G – 710G Nozzle inserts with thermal centering are available.

| Type | Pipe range in mm from – to |

ca. power in kg/h |

Heating power kW |

Heating zones |

|---|---|---|---|---|

| PVC 25 G | 10 x 1,0 – 25 x 1,9 | 60 | 1,50 | 2 |

| PVC 32 G | 12 x 1,0 – 32 x 3,6 | 100 | 2,0 | 3 |

| PVC 63 G | 16 x 1,8 – 63 x 4,7 | 150 | 6,0 | 4 |

| PVC 75 G | 20 x 1,5 – 75 x 5,6 | 250 | 6,5 | 4 |

| PVC 110 G | 32 x 2,4 – 110 x 8,2 | 350 | 7,0 | 5 |

| PVC 160 G | 63 x 7,0 – 160 x 7,7 | 500 | 12,0 | 5 |

| PVC 200 G | 63 x 7,0 – 200 x 5,9 | 600 | 13,0 | 6 |

| PVC 250 G | 90 x 4,3 – 250 x 7,3 | 650 | 20,0 | 6 |

| PVC 315 G | 125 x 13,9 – 315 x 9,2 | 700 | 32,0 | 8 |

| PVC 400 G | 160 x 7,7 – 400 x 11,7 | 800 | 42,0 | 9 |

| PVC 500 G | 225 x 6,6 – 500 x 23,9 | 900 | 48,0 | 10 |

| PVC 630 G | 250 x 7,3 – 630 x 18,4 | 1000 | 60,0 | 12 |

| PVC 710 G | 400 x 7,9 – 710 x 14,0 | 1000 | 66,0 | 14 |

G+G_PVC-U-Rohrwerkzeuge (PDF / 63.85 KB)